Pcb Panelization

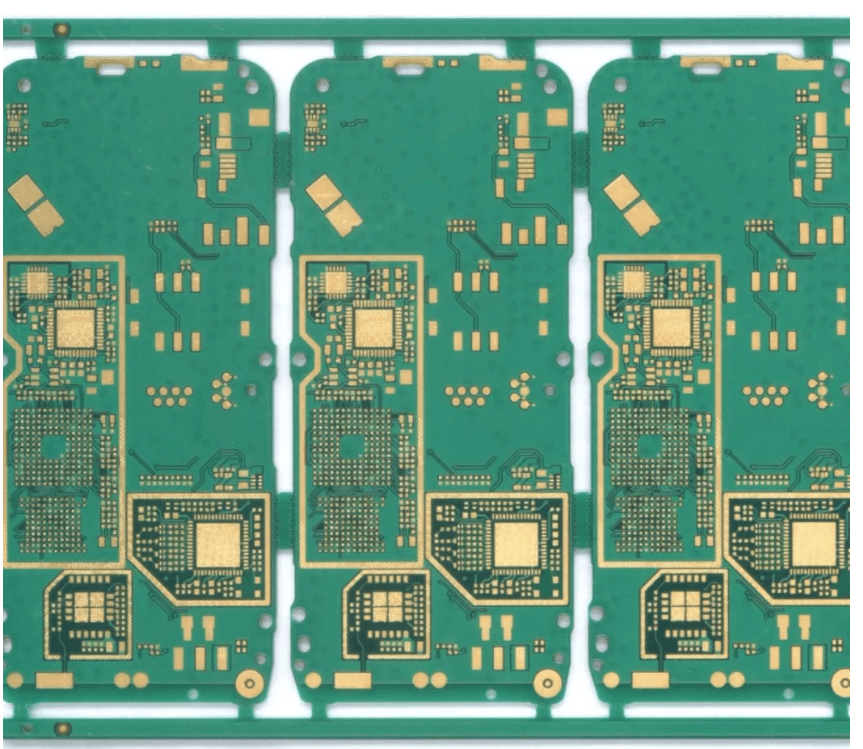

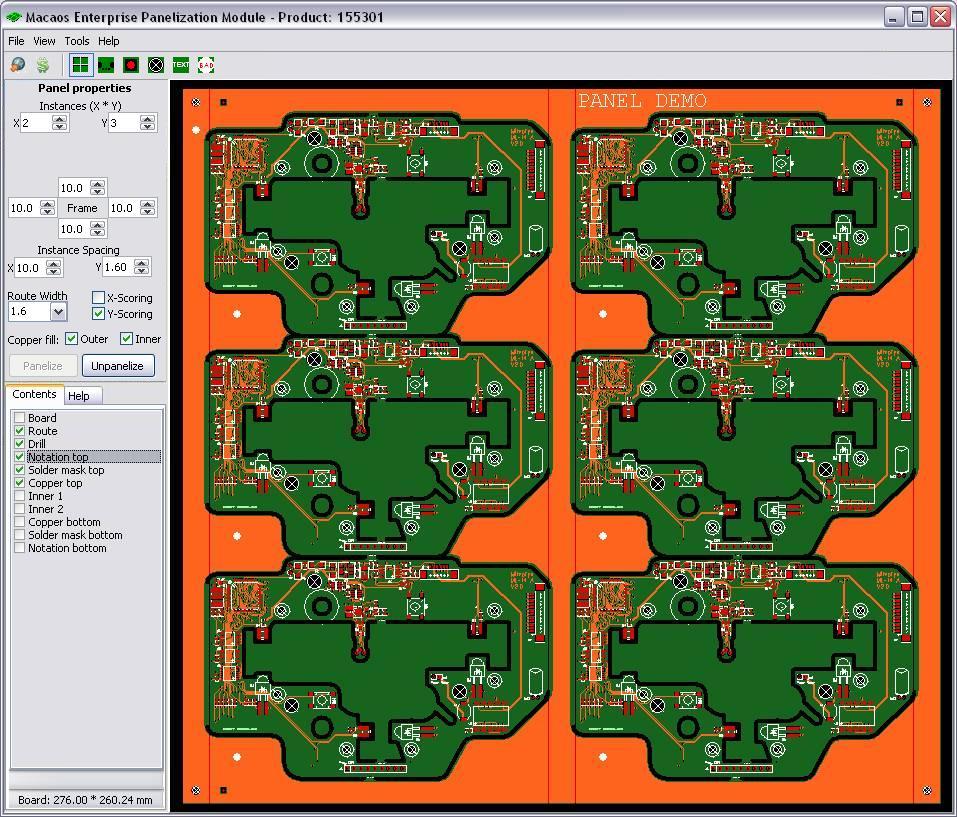

Three to five holes are often used in these perforation patterns. 2 panelization= 2 designs, maximum is 9 designs.

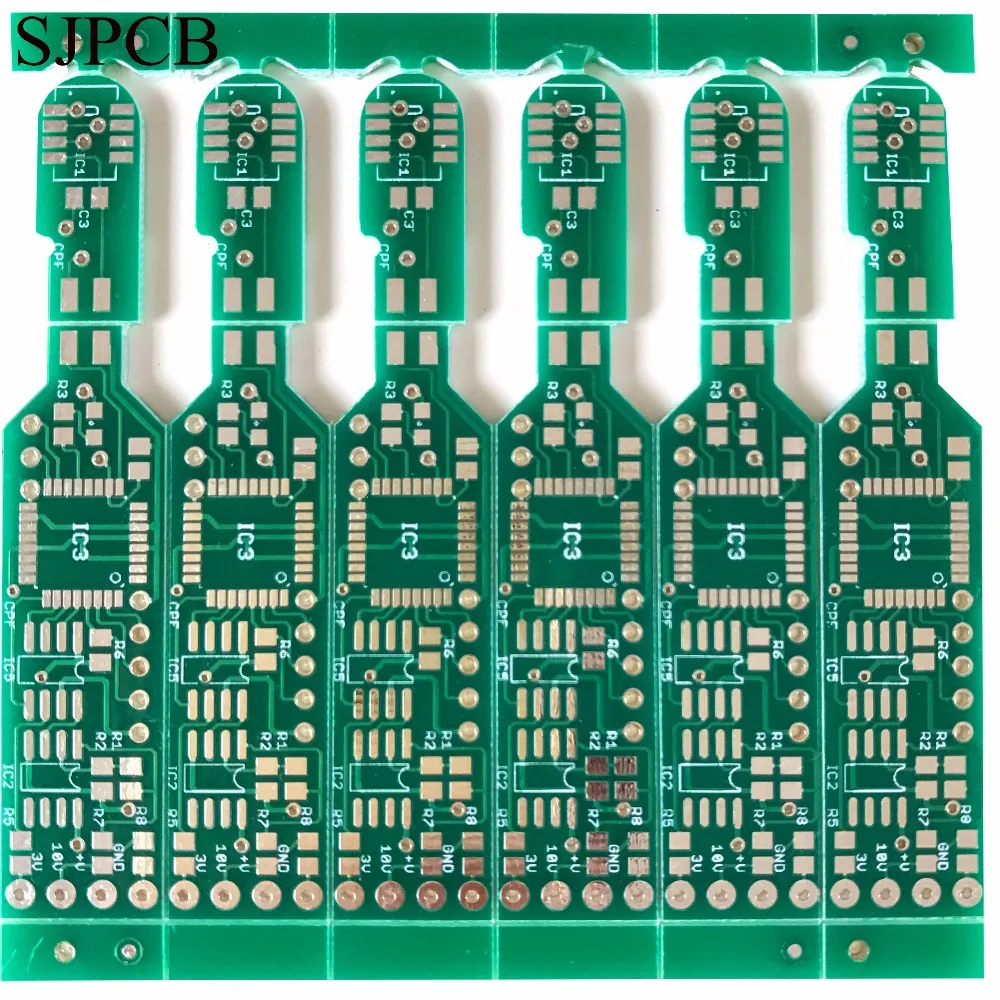

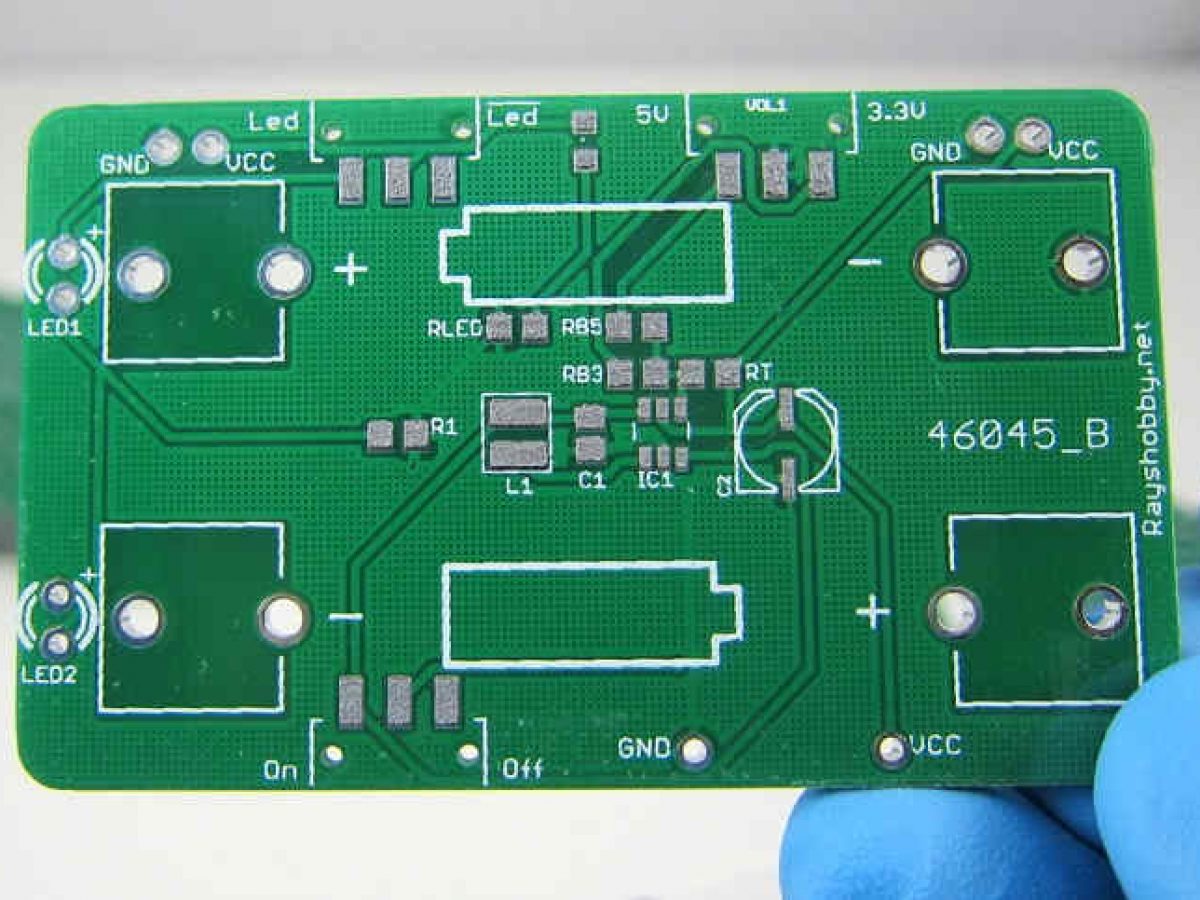

SJPCB Special Shape Outline Cut Circuit Board in Panel

Pcb panel, also referred as pcb array, is important for pcb manufacturing and assembly, and it helps to keep smaller pcb boards attached to one another in larger array.in this cam dealing process, we call it as pcb panelization.the purpose of pcb panel is to secure pcb boards during manufacturing, assembly, depanelization and shipping as painless as possible.

Pcb panelization. The individual boards can easily be depanelized or removed from the array for packaging or installation into a product. Once the pcb panel is produced, individual pcb boards will be removed. The benefit of the printed circuit board panelization process is a decrease in defects as automated assembly.

This is done to ensure that the format of the received. We know you want to save money but this may make it hard to cut the board outline and more importantly, this will take a lot more time to pick up and package the pcb. Pcb panelization is one of the most essential modern tools we have when it comes to pcb manufacturing efficiency.

The pcb panelizing tool then creates these panels to produce a complete circuit board. To minimize these defects and improve the throughput of the manufacturing process, many companies use a process called panelization, resulting in a pcb panel. These two methods join pcbs together in different ways and you might choose one over the other based on the design of your pcb.

There are two main types of pcb panelization: Pcb panelization guidelines automated circuit board assembly equipment often has trouble working with smaller boards, resulting in more frequent defects during the assembly process. The standard board thickness value must be.

Pcb panelization guidelines for layout. Pcb panelization is not only suitable for producing smaller circuit boards but also leads to an efficient production process. A pcb panel, also called a pcb array, is a single board consisting of multiple individual boards.

Pcb array panelization is a critical step in the assembly process and presents the greatest challenges to pcb designers. To enjoy the benefits of everything about pcb panelization, it's critical to factor some design. The following are common advantages of pcb panelization:

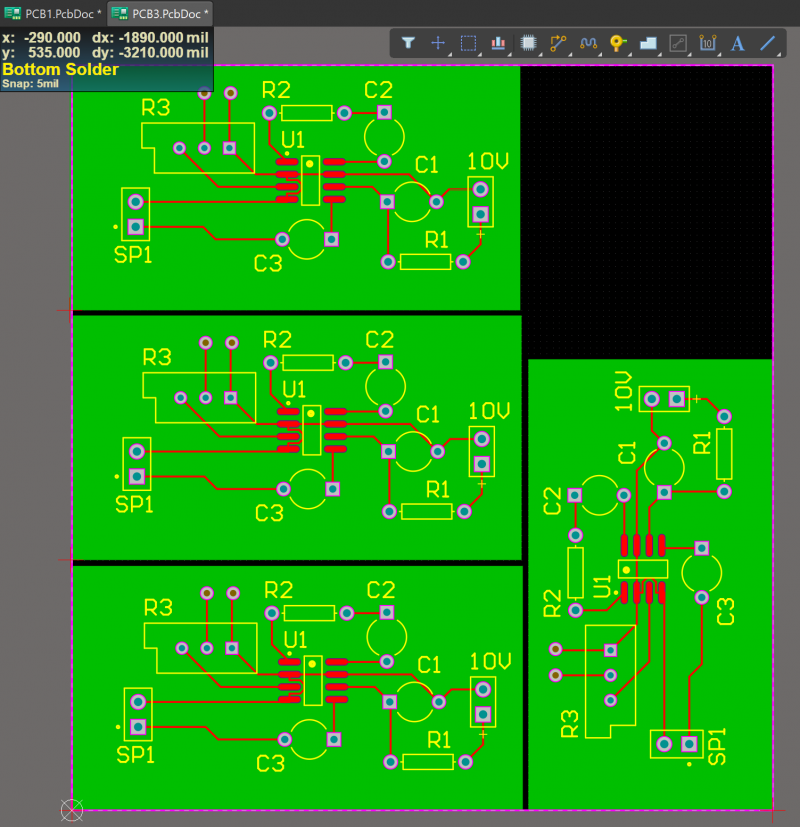

The pcb data is sent to the pcb manufacturing company along with a panel design specification after the pcb design is being finalized. A) p ut all designs in one gerber file. The goal during manufacturing is to reduce the labor, materials, and chance of errors during production while improving the precision and quality of the final product.

With pcb panelization, designers can estimate the total number of boards that will fit a panel. Panelization is a process of arranging multiple boards in an array on a single panel with a standard size. Asides performance, compliance with the standard requirements, and functionality, there's a need to include manufacturability as a factor into the designs of your printed circuit boards.

Panelization is the process of breaking a pcb design up into smaller pieces so that, for example, it can be manufactured more easily and efficiently. Pcb panel is also called pcb array or pcb matrix.the panel can include one design or multiple different designs. This technique exists because many production machines cannot process boards below a specific size.

The panelization of pcbs is a method through which many pcb boards are constructed/assembled by a single board (called pcb panel). Think of it as building copies of your board on one large pcb substrate. Pcb panelization is the process of manufacturing small circuit boards as part of a single, broader array.

Pcb panelization saves both time and money and is the best technique for the mass production of circuit boards. If you want to create a large number of boards, panelization will minimize costs and condense your lead times.; Pcb panelization can not only improve the production efficiency of pcs and reduce delivery time, but also solve many logistics problems by using pcb panels correctly, including how to manufacture smaller printed circuit boards or boards with.

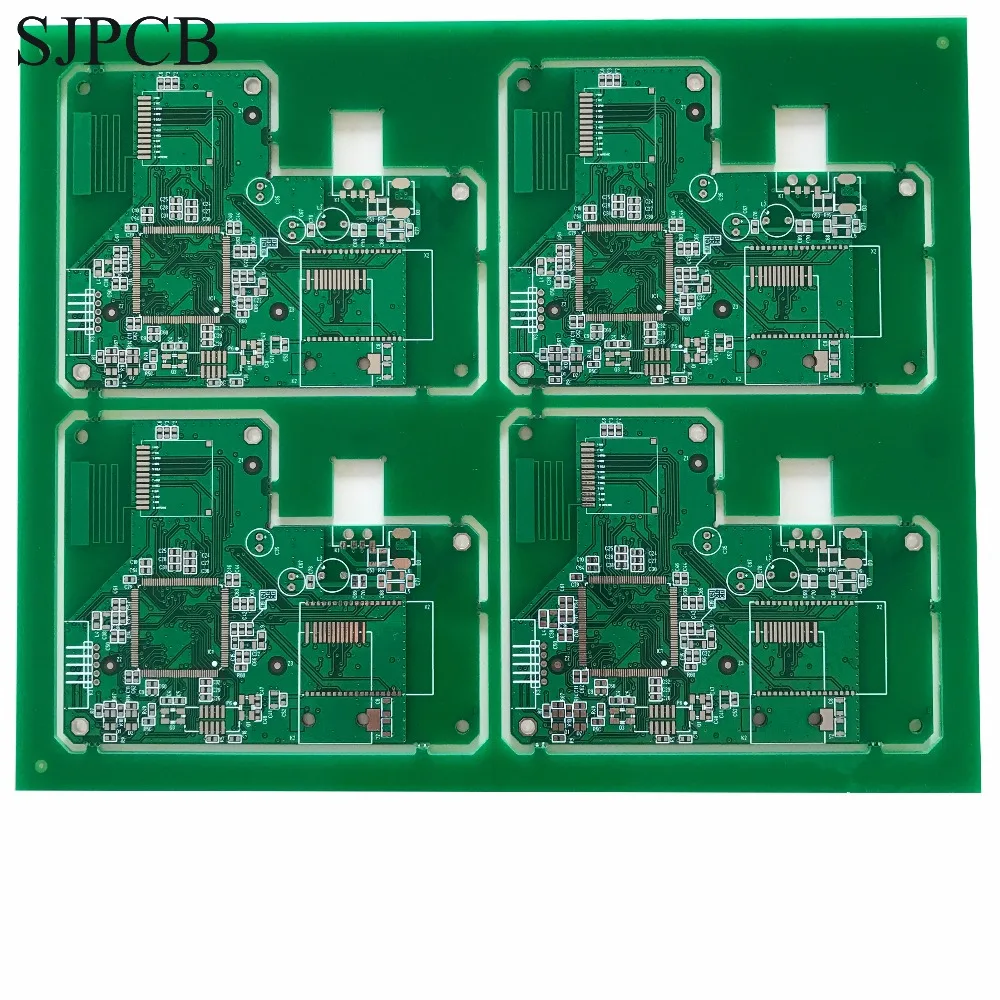

If the panel only includes one piece or single board, it is 1up. Pcb panelization enables smaller boards to fit in standard manufacturing processes and makes manufacturing more effective. This is true in pcb manufacturing as well, and to help with this goal, pcb designers need to understand how their layout decisions will.

Some customers would like to merge more than 1 pcb in the same gerber. Panelization shields the board from shock and vibrations produced. Once assembled, the panel is then broken apart, or depanelized, into the individual pcbs during the breakout process.

C) choose panelized pcbs option, ie. Also, there is an opportunity to make changes. These dimensional changes indeed help manage costs and improve panel utilization.

The primary benefits of pcb panelization are: When it comes to the efficiency of pcb manufacturing, one of the most essential modern tool that comes into picture is pcb panelization. Making the boards together, then breaking them apart along predetermined fault lines, solves this problem.

B) make sure the cut lines (slots) are in outline layer (gko/gml), and the complete board outline should go all round the edge of the boards. Pcb paneling, which reduces time and money, is the most widely used process for the production of pcb. Why pcb panelization is important.

In designing pcb, you need to get many things right. Pcb panelization, is a manufacturing technique, in which several small printed circuit boards are grouped together by cam engineer or designer for forming as a panel. Designing boards having panelization on your mind will help in preventing redesigns and delays that are unplanned.

SJPCB Panelization Required 2*2 Same Board Production

Panelization in Designing PCB to Production

KiCad PCB Panelization with Javascript

Panelization Design Guidelines When Using Common PCB

Why PCB Panelization is for You! Advanced Assembly

PCB Panelization Using The Embedded Board Array Altium

Why is PCB panelization important? RCY

Pcb Panelization Software Free Pcb Circuits

Pcb Panelization Software Pcb Circuits

Pcb Panelization Software Pcb Circuits

Why You Should Consider PCB Panelization During Design Tempo

Pcb Panelization Software Free Pcb Circuits

Use All That Extra Space With PCB Panelization Hackaday

How to Build a PCB Panelization What is it and Why? EEWeb

Panelize Pcb Altium Designer Circuit Boards